At Top Tubes, we offer an end-to-end service that takes your tube further. This means we provide a complete manufacturing process to deliver custom tubing fit for your application.

Our service includes the design of all types of tubing, as well as manufacturing and fabrication operations such as coil slitting, laser cutting, and bending.

In this guide, we talk you through each process and how we can cater for your project requirements…

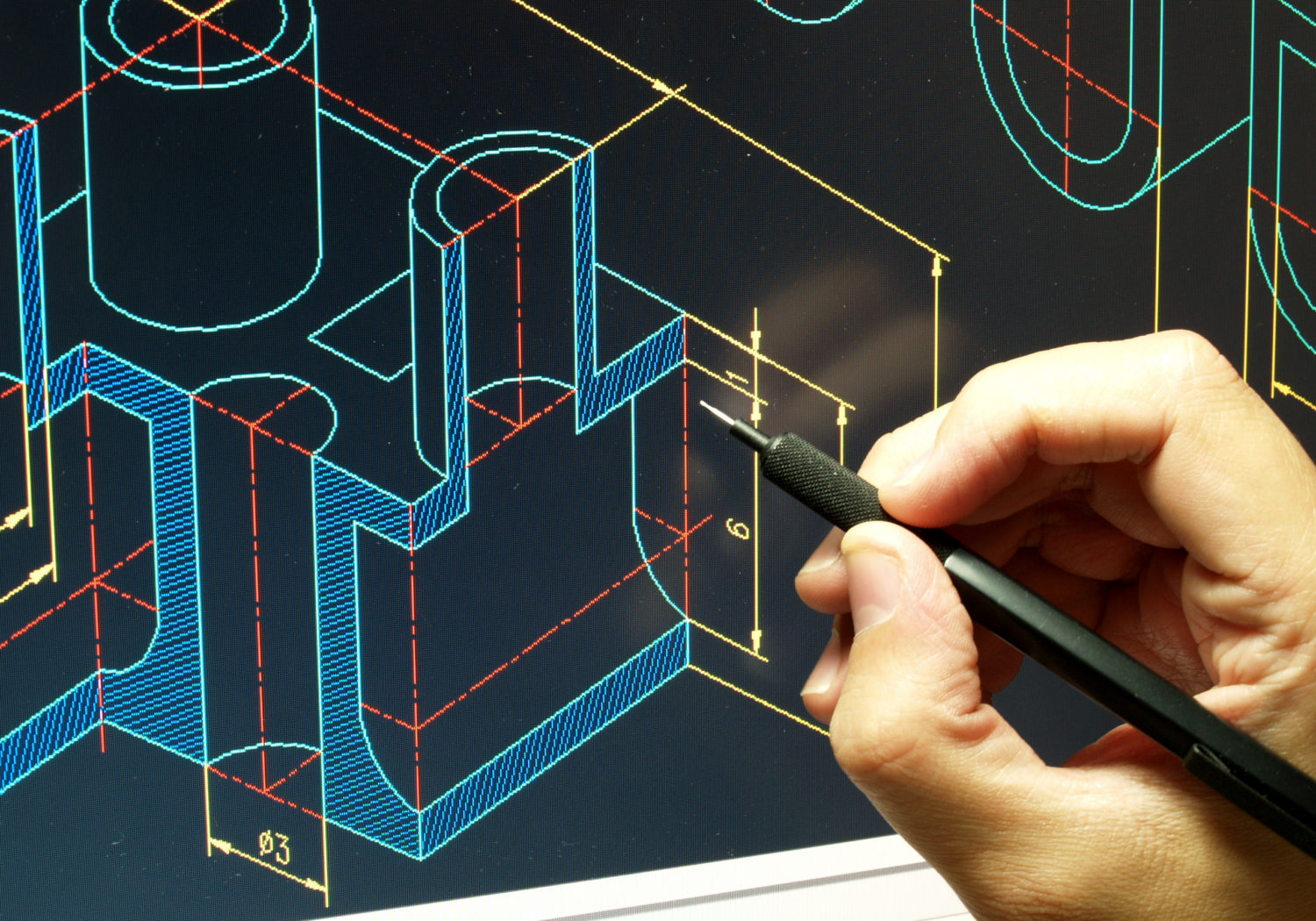

Design and Specification

Top Tubes offers design advice and feasibility on the production of your tube. We work across all types of industries to supply tubing, and have vast experience and expertise in our craft to provide you with the most cost-efficient and quality tubing.

Our design capabilities include reverse engineering. Our team can reverse engineer all types of tubing to determine the right route to manufacture to emulate or update existing and antiquated tubes.

These design capabilities are supported by CAD technology, ensuring our engineers can meet demanding project specifications with complete accuracy and efficiency.

At Top Tubes, our specialised services cater to your needs in designing and manufacturing precision laser-cut tubes. Our proficient team excels in handling sample orders tailored to your specifications, utilising our advanced software to adapt and reproduce them precisely to your requirements.

We take pride in our commitment to precision, ensuring that only our laser machines cut corners while tirelessly striving to consistently meet your exacting standards and specifications.

What is reverse engineering?

Reverse engineering is the process of dissecting or analysing a product to understand how it works. This is undertaken by specialist equipment and can inform upcoming manufacturing processes.

What is CAD?

CAD stands for Computer Aided Design; this is the use of computer software to assist the creation, modification, analysis and optimisation of product designs.

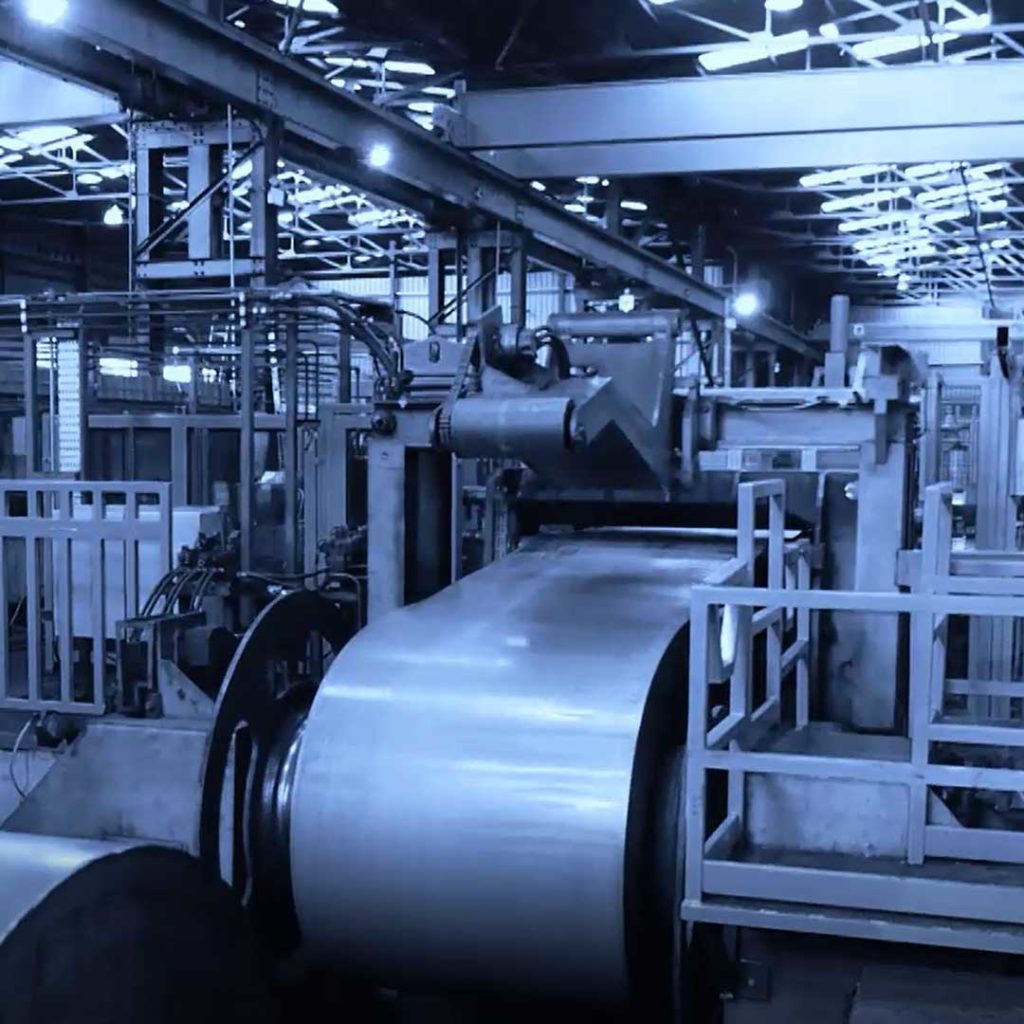

Coil Slitting

When producing tubing, the first step of the process is generally decoiling and slitting. Tube is supplied as a large coil of sheet metal, which is then slit vertically into customised width strips as it unwinds. Slitting saws, rotary shear slitters and razor slitters can all be used on slitting machines to cut the sheet metal into different widths as per project specifications.

These individual strips of sheet metal are turned into tubes in later production, ensuring minimal material waste from the original coil.

After slitting, the individual lengths of material may be edge-trimmed, levelled, or cut to length in preparation for further fabrication processes.

Top Tubes works with hot rolled steel, cold rolled steel, galvanised steel, and aluminium for our coil slitting operations, with a large number of steel grades available to meet your requirements. This operation is then followed by the formation of tubing in our state-of-the-art tube mill. You can now find out more information about Coil Slitting Services here.

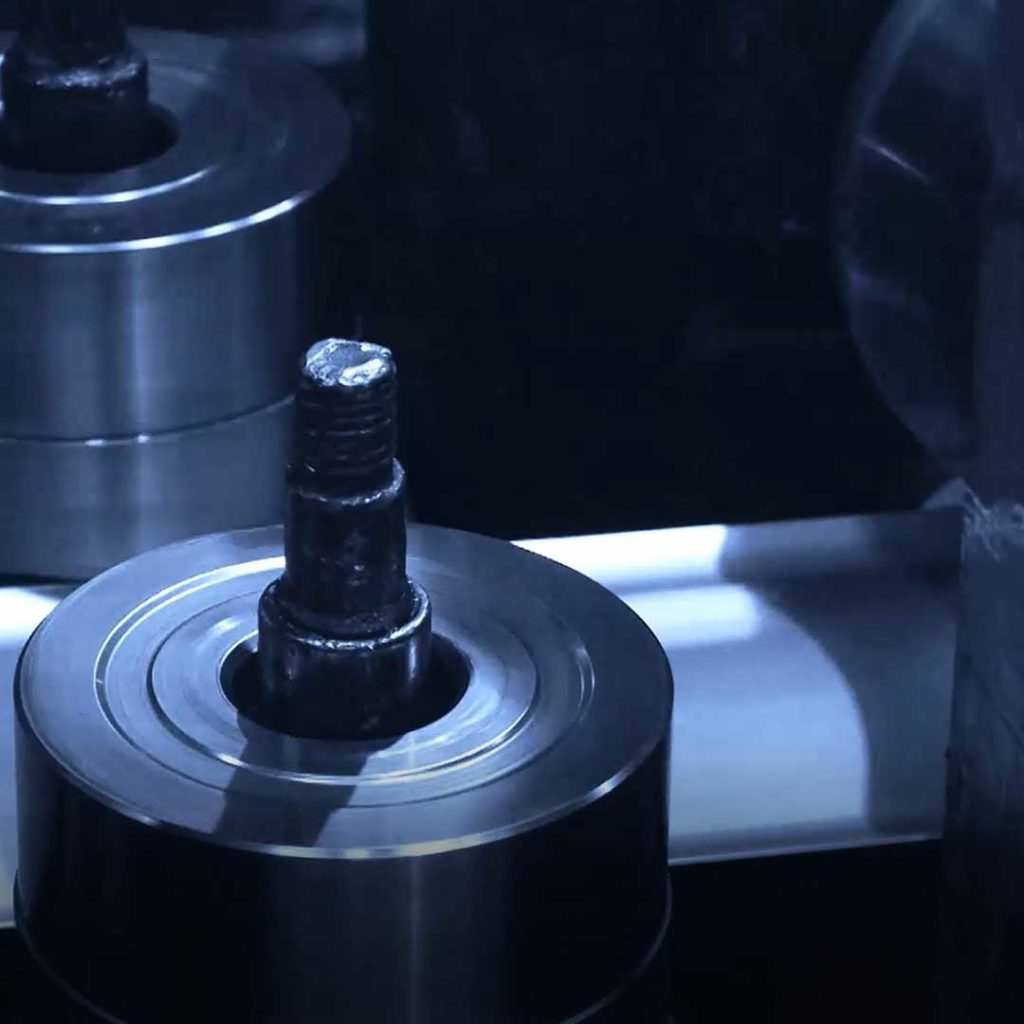

ERW Tube Manufacture

What is an ERW tube?

Electric resistance welded tube, or ERW tube, is a seam welded tube, and appears without an obvious weld seam. It is created by welding a tube together along its length, following its formation in a tube mill; excess weld known as ‘Fincle’ is then removed from the inside of the tube.

At Top Tubes, we supply ERW tubes, an essential product in keeping our service as cost-efficient and as effective as possible.

It’s a more cost-efficient alternative to seamless tubing, whilst maintaining the quality and durability expected of a seamless tube.

Top Tube’s ERW tube is available as pre-galvanised, offering around 5-10 years of longevity, and Magna tube, which boasts an impressive 30 years of performance. We further offer hot-dipped galvanised tubes for customers that require it.

Our large capacity for the production of ERW tubes ensures we can take on tube ranges from 2000 mm to 13500 mm in length, all with clean cut sheared ends. This includes round, square, rectangle, flat sided oval, and special section as required, with finishing options of uncoated, semi-bright, pre-galvanised, aluminised, and perforated.

To find out more on how our ERW Tube can take your business further, click here to find out more.

Get In Touch

Our expert team is ready and willing to assist you with all your manufacturing needs, simply click the link.

Laser Cutting and Tube Slotting

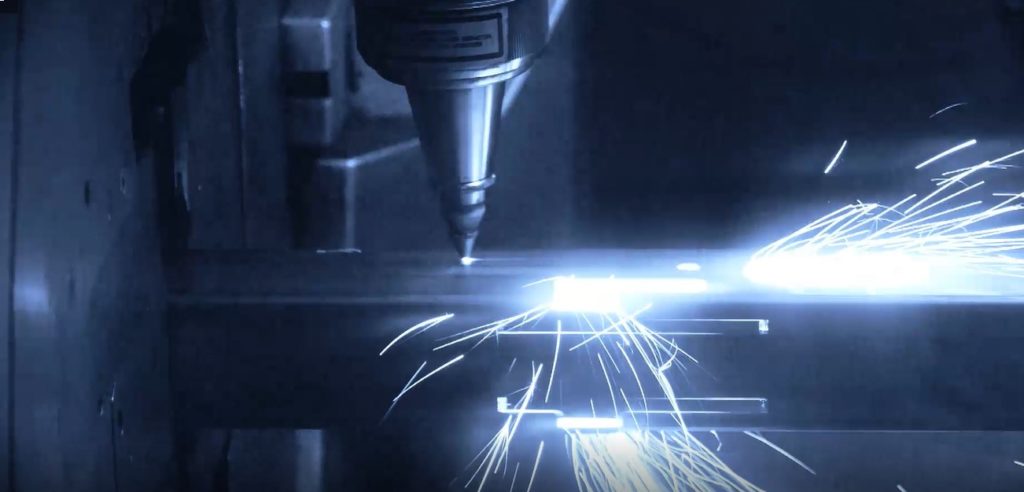

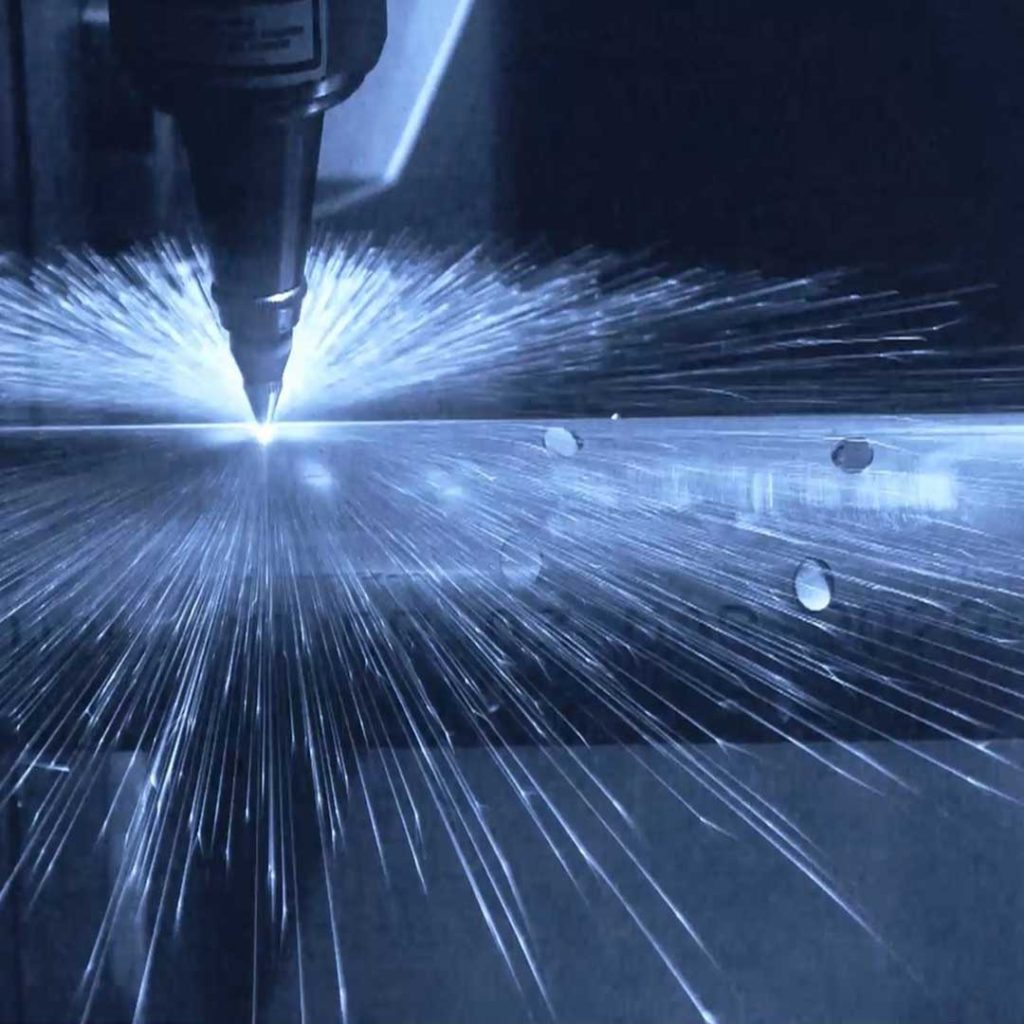

Laser cutting is frequently used in the production of tubing to cut the material to length and perform slotting operations.

Laser cutting offers many benefits over traditional methods of cutting tube, including heightened precision, speed and repeatability. Laser cutting is a flexible process, and can be easily adapted to a range of specifications, with the ability to cut through a number of materials and material thicknesses.

Top Tubes works with a range of metallic materials, including stainless steel, and with laser cutting we’re able to work to a varied range of project requirements. As a part of this, we produce our own nitrogen to fuel laser operations, reducing our dependence on external suppliers and enhancing our ability to meet demanding project timescales.

When working with pre-polished materials, such as stainless, we take additional precautions to ensure the risk of scratches is reduced to maintain the integrity of the material. Laser cutting is recommended for these applications since the machinery does not come into contact with the material, unlike traditional methods of cutting.

For more information on our laser cutting capabilities click here to find out more.

What is slotting?

Slotting removes material from the end of the tube, in a long and narrow formation to create an aperture. This typically appears as either a straight or rectangular slot, however more complex designs can be achieved with laser cutting.

What is laser cutting?

This process involves directing a high-powered laser through optics to focus and control the laser beam’s intensity. The focused laser beam then melts, burns, or evaporates the material, penetrating through the metal to produce a clean cut.

Metal Fabrication Processes Under One Roof

From design conception to laser cutting and slotting, Top Tubes specialise in producing quality tubes that meet all of your specification requirements.

Our range of in-house fabrication processes and expert team ensures we can implement the most efficient methods for your unique product. This service is complete by our delivery capabilities, meaning tubing can be safely delivered to your door.

We utilise our own transportation fleet to achieve this, ranging from a 3.5-ton flatbed to 44-ton articulated vehicles, with the capabilities to deliver throughout the UK and to Europe.

For all your tube requirements, Top Tubes can guide you throughout the whole process for a finished product you can trust.