Reprinted from Business Report West Midlands, Nov/Dec 2011

“Taking tube further” reads the strapline on every page of the new-look website of Top Tubes. Putting its philosophy into practice, the Wednesbury-based company, which already offers a greater range of capabilities than any other UK ERW steel tube producer, has this year invested £1.5 million in new plant and achieved accreditation to ISO 9001:2008 to secure its leading position in the industry.

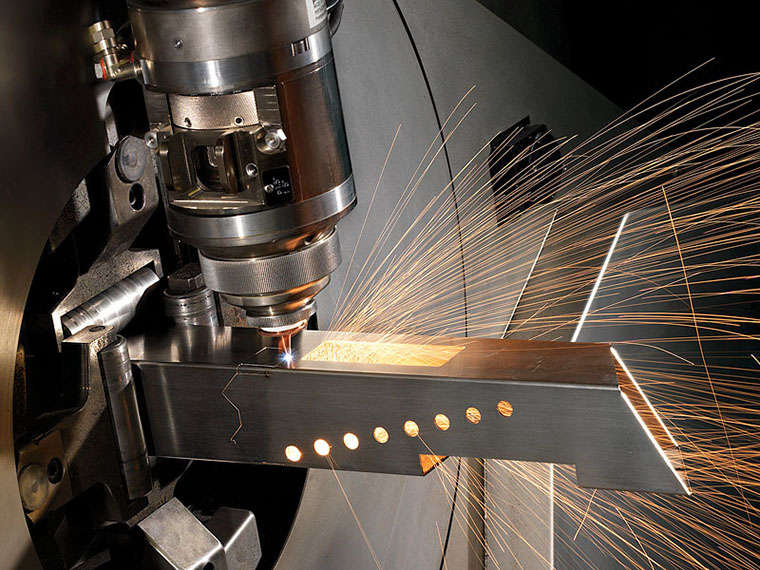

The company’s newest piece of equipment is a £800,000 BLM Adige LT8 laser-cutting machine, the most advanced of its type. It can process square tubes up to 200mm x 200mm and rectangular tubes up to 200 x 180mm. Complementing the company’s existing LT712D and LT722D machines, two of the fastest of their kind in the world, the LT8 gives Top Tubes a complete range of laser-cutting services covering all tube dimensions.

Other equipment purchased in the last 12 months includes a £250,000 Mair automated packing line, which will enable tubes previously delivered in irregular bundles to be presented to customers in neat rectangular, square or hexagonal packs. In addition, a new high-speed Bruderer perforation line, costing £150,000, means perforated strip processing can now be handled in-house, and so better controlled, rather than outsourced. In a similar move, early next year a slitting line will be installed to replace facilities currently sited at another factory.

Craig Gibbs, ERW sales manager, said: “Our aim is to be a solutions provider, not just a tube producer. By offering added-value services, such as laser profile cutting, manipulation and fabrication, we can deliver to the customer a semi-finished product with a finite cost.”

The company’s accreditation to ISO 9001:2008 marks the culmination of two years’ work which has seen Top Tubes not just introduce new procedures but also a new working culture. “We have changed the way we work to achieve this standard,” said managing director Adam Bradley. “Everybody is now completely focused on this quality management system and understands why it is so important we use it to control our working practices.

“Not having this standard has held us back in the past. Many companies would not even talk to us. Now just weeks after gaining our accreditation, it is already beginning to open doors. It will give us the opportunity to supply products for higher-end applications to OEMs in the automotive sector and other market segments that we were previously closed out of before.”

Top Tubes was established in 1994 – by Adam and his brother Matthew – and ever since its turnover has grown consistently, from £1.5 million in its first year of trading to £28 million in 2010. Today the company employs 100 people while annual output currently stands at more than 30,000 tonnes.

“The investment in new equipment and our quality improvements are taking Top Tubes into a new era in terms of capability, efficiency and professionalism,” added Adam. “Despite our rapid growth, Top Tubes still has the atmosphere of a small, close-knit business. Because the company is family-owned, we have many good qualities – such as our dedication and sense of endeavour – which I think sets us apart from many of our competitors.”