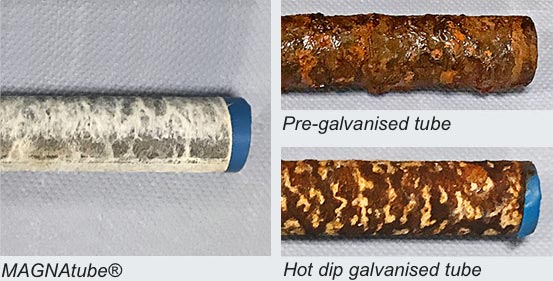

MAGNAtube® sets a new standard in corrosion-resistant coated steel tube: up to 20 times the corrosion resistance of galvanised tube, the durability of high-strength steel, self-healing anti-corrosion properties, better processing capabilities than post-galvanised tube, plus the added benefit of environmental sustainability.

MAGNAtube®’s evolutionary zinc/aluminium/magnesium coating withstands the most hostile conditions, including alkaline and ammonia rich environments. Furthermore, in exhaustive tests conducted by leading UK test house Rotech Laboratories MAGNAtube® lasted the equivalent of 100 years without significant deterioration.

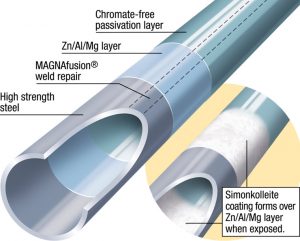

With unique MAGNAfusion® weld repair, 100% exterior and interior protection is guaranteed. This, together with MAGNAtube®’s tough scratch-resistant surface, offers extreme product longevity.

- Up to 20 times the corrosion resistance of galvanised tube

- High strength steel

- Greatly extended product life

- Edge protection

- Enhanced formability

- Total exterior and interior protection

- Unique MAGNAFusion™ weld repair

- Harder more resilient surface

- Environmental sustainability

The Simonkolleite Factor

The magnesium content within the coating forms an additional highly stable layer called Simonkolleite which completes a triple level of unrivalled protection both outside and inside the tube. Even cut edges are protected by the spreading of this Simonkolleite layer.

Comparison tests

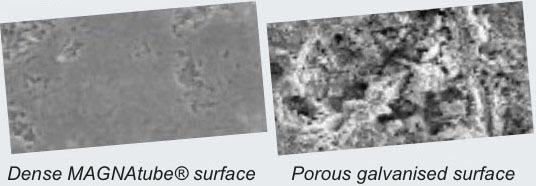

Surface Density

The corrosion resistance of MAGNAtube® is due to the dense protective layer formed on the outer and inner surfaces of the tube, in contrast to the porous surface of galvanised tube.

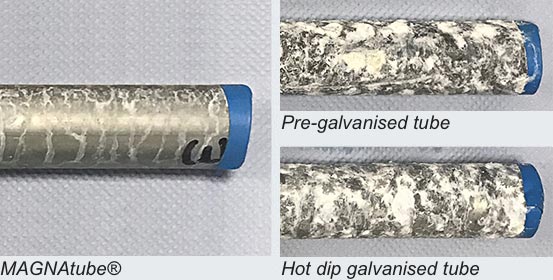

120 Hour Salt Spray Test

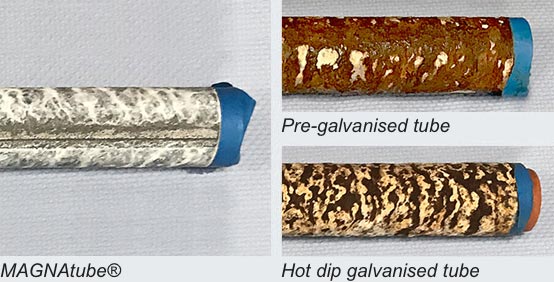

1392 Hour Salt Spray Test

3000 Hour Salt Spray Test

MAGNAfusion™ weld repair

Top Tubes’ unique MAGNAfusion™ weld repair, carefully formulated to precisely match the characteristics of the rest of the coating, ensures consistent exterior and interior surface protection, resulting in the same level of corrosion resistance throughout.

Typical Applications

Solar Installations

MAGNAtube® is perfectly in line with environmental objectives, of which solar energy is a part.

Its extended life reduces resource-wasting maintenance, often in remote areas, plus it reduces manufacturing resources, and contributes to lower amounts of zinc in the atmosphere.

Superior surface hardness suits MAGNAtube perfectly to external environments and corrosion-resistance in soil is a particular benefit in this context.

Agricultural applications

MAGNAtube® is the ideal answer to the alkaline and ammonia-rich conditions found where livestock are present and its superior surface hardness means that MAGNAtube® resists scratches and abrasions caused by animals.

Increased corrosion resistance in soils is another benefit of MAGNAtube®. Silos also form an ideal application where surface hardness resists scratches caused by grain.

Greenhouses and Polytunnels

The humid, warm environments of greenhouses and polytunnels are a prime breeding ground for corrosion, making MAGNAtube® the ideal tubular component within these structures.

In addition, MAGNAtube® offers far better protection when in contact with soil than galvanised tube.

Construction

In the construction industry longevity and low maintenance are vital elements, which means MAGNAtube®’s long service life is a perfect solution.

Not only that, MAGNAtube®’s high scratch and abrasion resistance is invaluable in construction applications, and when in contact with the alkaline conditions created by concrete, MAGNAtube® shows much greater corrosion resistance than galvanised tube.

Rail Infrastructure

The greatly increased lifespan of MAGNAtube® compared to galvanised tube suits it perfectly to lineside structures and overhead electrification, where reduced maintenance and long service life in a variety of climatic conditions are priorities.

The durability of high strength steel and resistance to abrasion in what can often be demanding applications are additional benefits.

Marine Applications

In coastal and maritime applications the high winds and salt-laden air causes corrosion to occur far more quickly.

MAGNAtube® is designed to resist corrosion in such conditions far more effectively than galvanised tube, providing a service life similar to that of aluminium and stainless steel but at a much lower cost.